Using plastics to produce auto parts has become increas […]

Using plastics to produce auto parts has become increasingly popular. These days, about 20% of the dry mass of a vehicle is made up of plastic. It is also possible to create lightweight auto parts with various injection molding processes.

Plastic components are often used in a variety of applications, including internal and external car components. Auto parts made from plastics can be durable and long-lasting, and they are less expensive than their metal counterparts.

Plastics can be molded into a variety of shapes, and if they are designed properly, they are also highly durable. Choosing the right mold maker can ensure the best results.

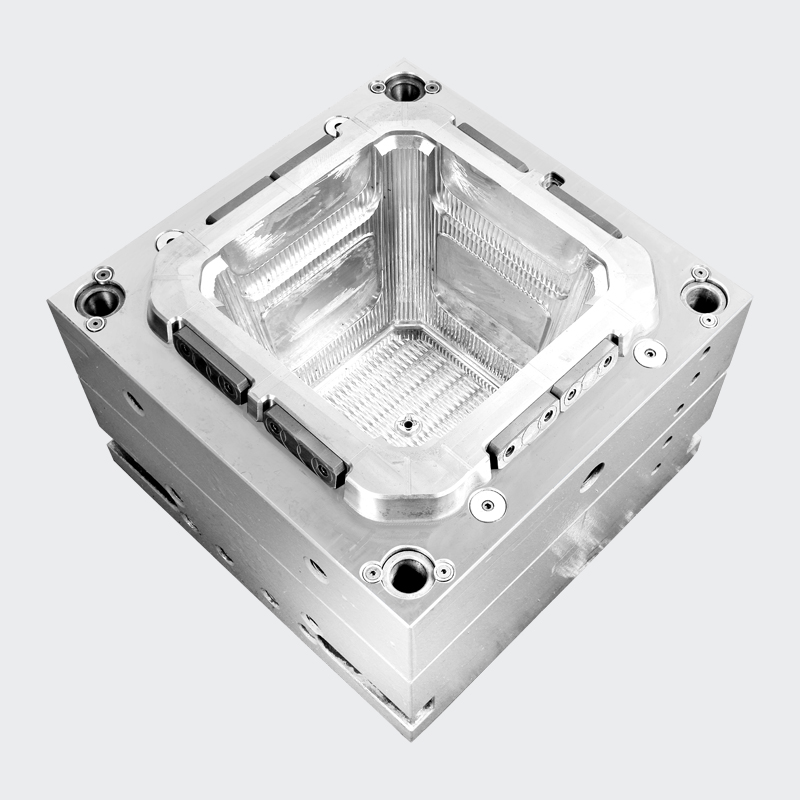

One of the most impressive auto parts production processes is injection molding. This method involves filling a specially-crafted mold with a liquid plastic. Then, the plastic hardens into the final component. The process is a lot faster than other methods, and it is also easier to scale up for mass production.

Another important aspect of injection molding is its ability to produce quality parts with superior surface finishes. These types of parts can be produced with speed, accuracy, and precision. Some of the most common types of plastics used in auto parts include polypropylene, PU, and PVC.

A good auto parts mould is important to the success of your product. It is also important to choose a mold maker with experience in the automotive industry. A mould maker should have injection moulding facilities as well as a good design team.

Aside from injection molding, the automotive industry also uses other techniques. Metal casting is one of the most popular methods for producing aluminum pistons and transmission housings. Other techniques include CNC machining and overmolding.