Die-casting die is one of the three major elements of […]

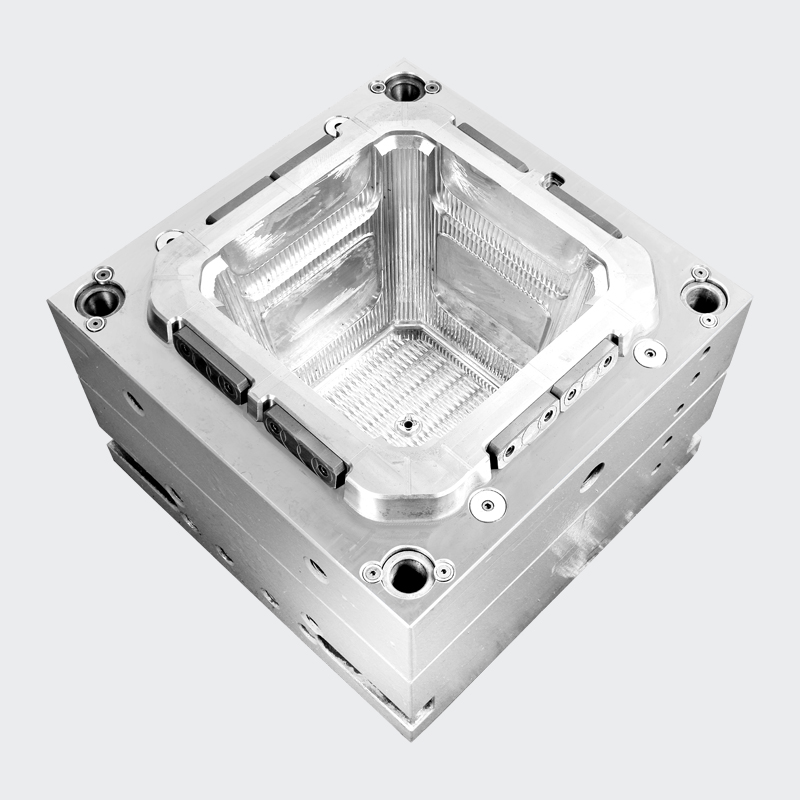

Die-casting die is one of the three major elements of die-casting production. A mold with correct and reasonable structure is a prerequisite for the smooth progress of die-casting production, and plays an important role in ensuring the quality of castings (the pass rate of the machine).

Due to the characteristics of the die-casting process, the correct selection of various process parameters is the decisive factor for obtaining high-quality castings, and the mold is the prerequisite for the correct selection and adjustment of various process parameters. The mold design is essentially the prediction of various factors that may appear in die-casting production. comprehensive reflection. If the mold design is reasonable, there will be fewer problems encountered in actual production, and the casting pass rate will be high.

On the contrary, the mold design is unreasonable. For example, when the casting is designed, the wrapping force of the movable and fixed molds is basically the same, and the gating system is mostly in the fixed mold, and it is produced on the Guannan die-casting machine that cannot be fed by the punch after injection, so it cannot be produced normally. The casting has been stuck to the fixed die. Although the finish of the fixed mold cavity is very smooth, the phenomenon of sticking to the fixed mold still occurs due to the deep cavity.

Therefore, when designing the mold, it is necessary to comprehensively analyze the structure of the casting, be familiar with the operation process of the die-casting machine, understand the possibility of adjusting the die-casting machine and process parameters, master the filling characteristics under different conditions, and consider the method of mold processing, drilling After the eye and the fixed form can be designed, the mold that is practical and meets the production requirements can be designed.