Plastic injection mold sometimes has some problems, whi […]

Plastic injection mold sometimes has some problems, which may lead to unqualified parts, such as: residual material in the mold, rust, cracks or other damage to the mold, and air or gas trapped in the mold. Product rejection means longer production cycles, so it is important to ensure that quality is maintained at a high level. So the self inspection and maintenance of plastic injection mold is particularly important.

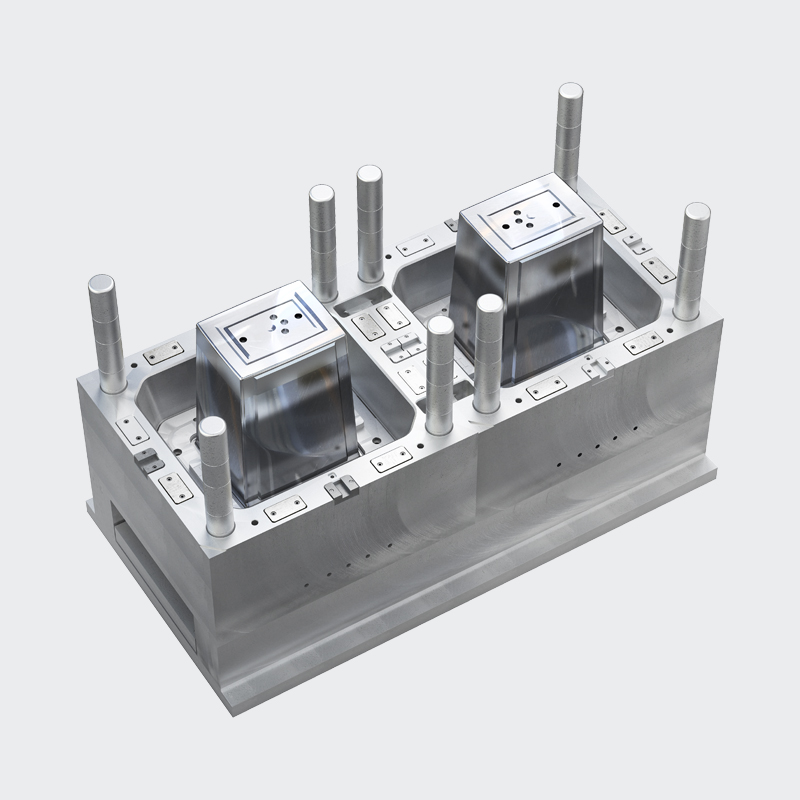

Basic plastic injection mold maintenance procedures

Basic maintenance inspection of plastic injection mold before and after each injection cycle. This will help keep the parts to specification and ensure that no debris or other foreign material damages the mold.

1. Clean the plastic injection mold cavity with mild solvent. The residual material in the cavity will affect the shape and structural integrity of the part. Simple cleaning helps a lot.

2. Use compressed air to blow out dust, debris and water. Especially in complex plastic injection molds, they can affect parts and cause more damage in the production cycle.

3. Before storing the mold, please make sure that the whole mold is completely dry. In order to avoid the plastic injection mold rust, rusty mold is more likely to fail or damage, and will produce a higher proportion of waste products.

4. Check runner, gate and all other areas of mold. It should be noted that the mold cavity is not the only area to be inspected during maintenance. Debris and water can also cause serious problems in other parts of the mold. Also make sure to check and clean these areas.

5. Check the hardware and connector of plastic injection mold. For example, bolts, plates and other parts. Check them for wear, fit, tightness and other standard maintenance issues.