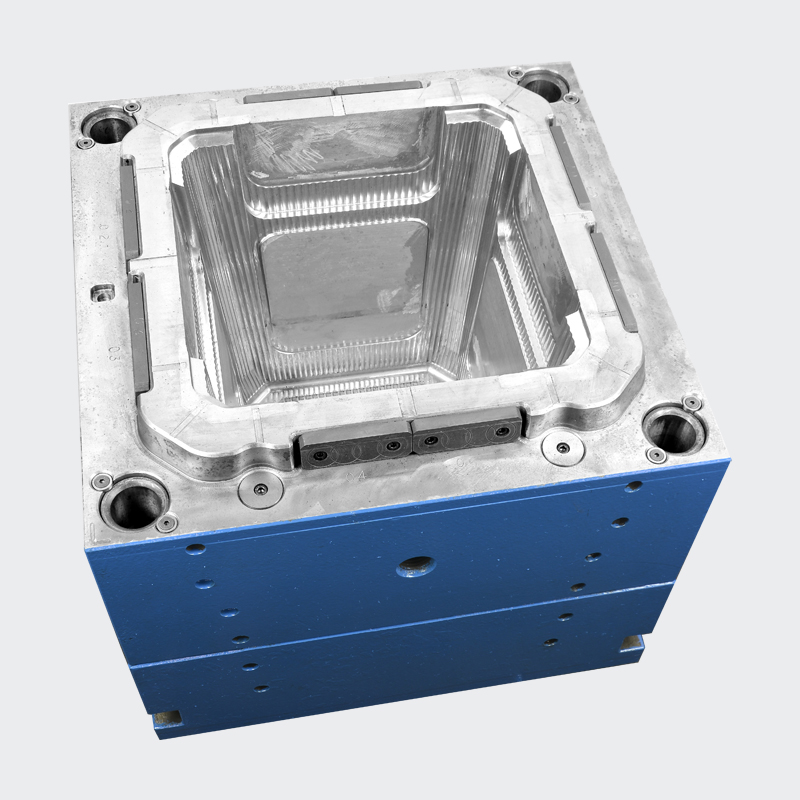

The following selection of more appropriate plastic mol […]

The following selection of more appropriate plastic mold needs to meet the following six requirements.

White base mold

1. Many resins and additives with high corrosion resistance have corrosion effects on the surface of the cavity, which makes the metal on the surface of the cavity dissolve and fall off, the surface condition deteriorate and the quality of the plastic parts deteriorate. Therefore, the best use of corrosion-resistant steel, or cavity surface chromium, cymbal nickel treatment.

2. Good wear resistance the glossiness and precision of the surface of plastic plastic parts are directly related to the wear resistance of the surface of plastic mold cavity, especially when some plastics are added with glass fiber, inorganic filler and some pigments, they move together with the plastic melt in the flow channel and mold cavity at a high speed, causing great friction on the surface of mold cavity. If the material is not wear-resistant, it will wear quickly, making the quality of plastic parts suffer harm.

3. Excellent dimensional stability in plastic molding, plastic mold cavity temperature to reach more than 300 ℃. For this reason, it is better to select tool steel (heat-treated steel) with proper tempering treatment. Otherwise, the microstructure of the material will be changed, resulting in the change of the plastic mold size.

4. Easy to process die parts are mostly made of metal materials, some of the structural shapes are very complex. In order to shorten the production cycle and improve the power, die materials are required to be easy to process into the shape and precision required by the drawings.

5. Plastic parts with good polishing performance generally require excellent luster and surface condition, so the surface roughness of the cavity is required to be very small, so it is necessary to process the surface of the cavity, such as polishing, grinding, etc. Therefore, the selected steel should not contain rough impurities and pores.

6. In order to improve the hardness and wear resistance, heat treatment is generally carried out for the plastic mold, but this treatment should make its size change very little. Therefore, it is best to select the pre hardened steel that can be machined.