In the plastic processing industry, the production of b […]

In the plastic processing industry, the production of baskets involves an injection moulding process. This process produces baskets, such as fruit baskets, laundry baskets and storage baskets. In order to produce a variety of different baskets, it is necessary to have a wide range of molds that can be used for each product.

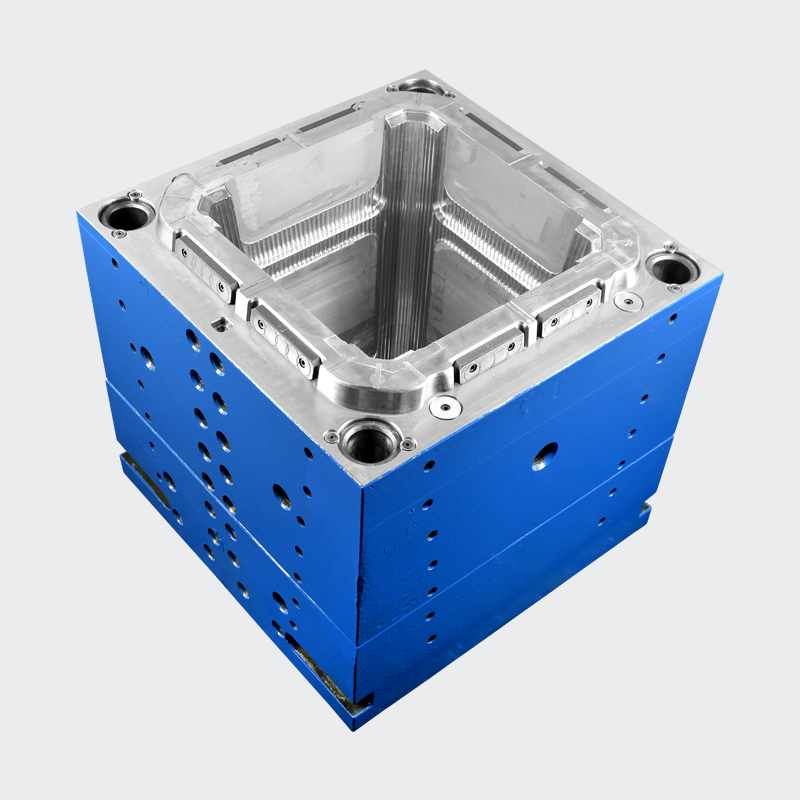

Basket molds are a type of injection mould that is widely used in the plastics industry. They can be made of a single piece or in smaller pieces that are then glued together to form the final mold.

Generally, there are two main parts to a basket mould: the core and the cavity. The core is formed by a tapered, circular channel that carries material from the nozzle of the moulding machine. The cavity is formed between the core and this channel, often with runners to aid in filling each cavity as efficiently as possible.

The runner system is usually made of channels that cut into the sides of one or both mould halves, and which run from the nozzle to the core. They are used to guide the flow of the plastics material into the core and into the cavities, ensuring that they are filled with the correct amount of material.

The body portion of the basket mold 1 is usually provided with a spindle hole 9 for receiving the spindle of a mold support or horse (not shown) mounted to the work table during the basket making process. This enables the spindle to be held in the base of the mold while the basket maker weaves the basket upon the mold.