With the development of science and technology, plastic […]

With the development of science and technology, plastic products have long become an irreplaceable product in our daily lives. In real life, plastic products have almost captured all areas, such as cars, boats, and airplanes that everyone can see at any time in life. , Computers, phones and other materials. Some of their plastic parts are injection molded by plastic molds. After a product is born, mold opening is essential. When we need to find a mold factory, we often think that injection molding Mold and plastic mold mean the same thing, so to understand the difference between plastic mold and injection mold, please read this article.

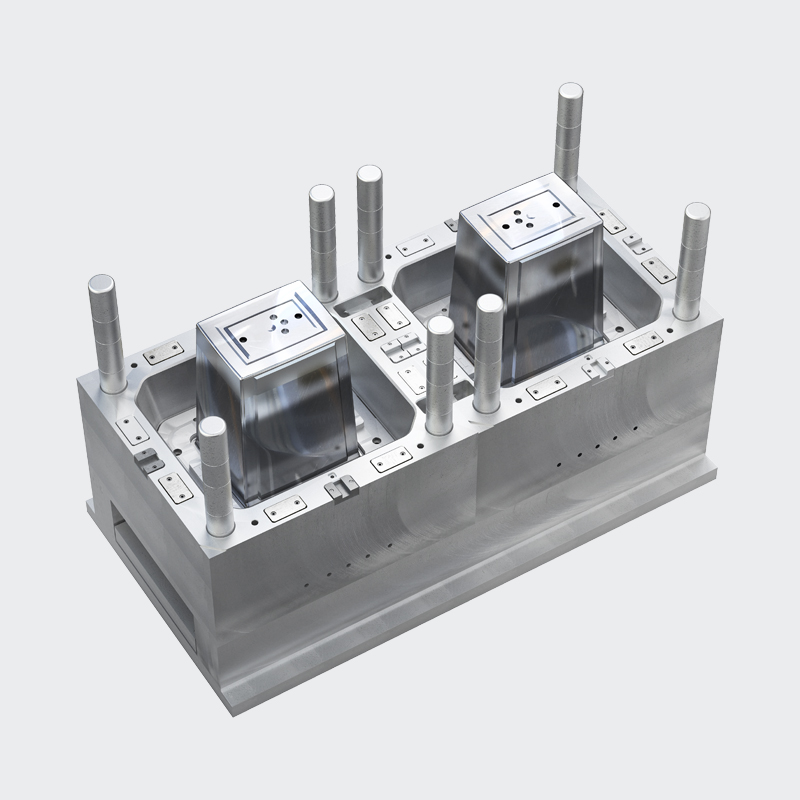

Plastic mold, a combined plastic mold for compression molding, extrusion molding, injection, blow molding and low foam molding, mainly includes a concave mold combined substrate, a concave mold component and a concave mold combined card board. The concave mold of the deformed cavity is a convex mold with a variable core composed of a convex mold combined base plate, a convex mold component, a convex mold combined card board, a cavity cut-off component and a side cut combined board. Coordinated changes of mold convex, concave mold and auxiliary molding system. Series of plastic parts of different shapes and sizes can be processed.

Injection mold is a tool for producing plastic products; it is also a tool for giving plastic products a complete structure and precise dimensions. Injection molding is a processing method used in the mass production of certain complex-shaped parts. Specifically, it refers to the high-pressure injection of the plastic melted by heat into the mold cavity by the injection molding machine, and the molded product is obtained after cooling and solidification. The injection mold is composed of a movable mold and a fixed mold. The movable mold is installed on the movable template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form a pouring system and cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic product. In order to reduce the heavy workload of mold design and manufacturing, most injection molds use standard mold bases.

It can be seen from the above content that there are still certain differences between plastic molds and injection molds, which also facilitates communication between us and plastic mold manufacturers to avoid making mistakes.

https://www.msplasticmold.com/