I; gating system The plastic mold gating system refers […]

I; gating system

The plastic mold gating system refers to the runner part before the plastic enters the mold cavity from the nozzle, including the main runner, cold feed cavity, splitter channel and gate. (Currently, the most commonly used hot runner system)

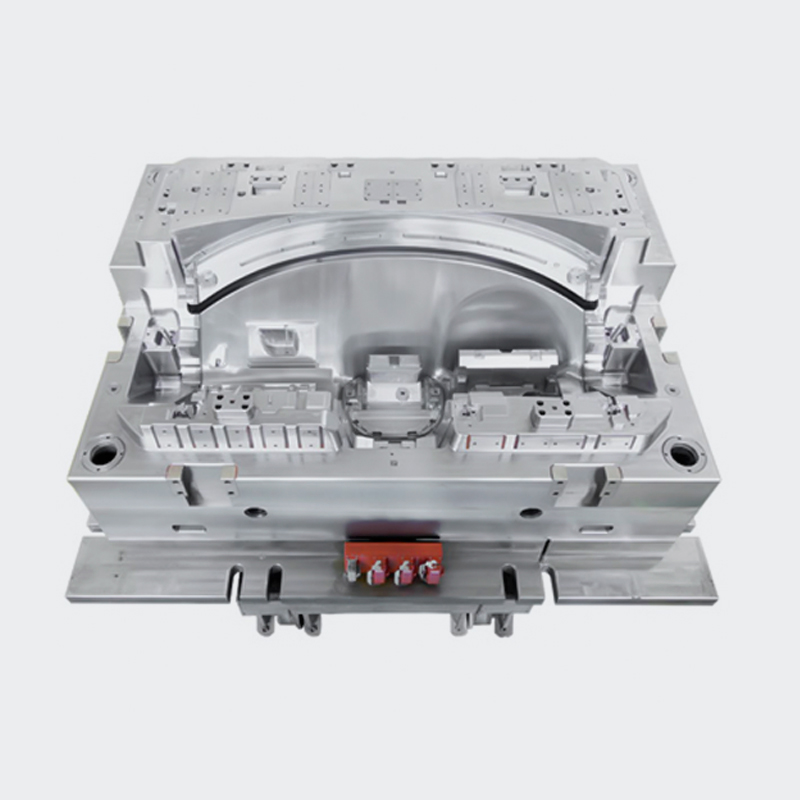

II; Forming system

Plastic mold forming part system refers to the combination of various parts forming the product shape, including moving mold, fixed mold, cavity (female mold), core (male mold), forming rod, etc. The core forms the inner surface of the product, and the cavity (female die) forms the outer surface shape of the product. After the mold is closed, the core and cavity form the cavity of the mold. (insert molding and stack mold, etc.)

III; Guidance system

The plastic mold guide system is set up to ensure that the moving mold and the fixed mold can be accurately aligned during mold closing. The guide components must be set in the mold. In the injection mold, four groups of guide posts and guide sleeves are usually used to form the guide parts. Sometimes, it is also necessary to set the inner and outer conical surfaces that coincide with each other on the moving mold and the fixed mold to assist in positioning.

IV; Cooling system

In order to meet the requirements of injection process for mold temperature, a temperature regulating system is required to adjust the mold temperature. For the injection mold for thermoplastic, the cooling system is mainly designed to cool the mold, and the mold can also be heated. (Extremely cold and hot technology is applied to the mold)

V; Ejection system

The ejecting system of plastic mould generally consists of ejector pin, front and rear ejector pin plates, ejector pin guide rod, ejector pin return spring, locking screw of ejector pin plate, etc. When the product is molded and cooled in the mold, the front and rear molds of the mold are separated and opened. The ejector pin, driven by the ejector pin of the injection molding machine, pushes or pulls the plastic products and the condensate in the runner out of the mold cavity and runner position, so as to carry out the next injection molding work cycle. (Secondary ejection and in mold hot cutting technology)