An auto parts mould is a specialized industrial tool th […]

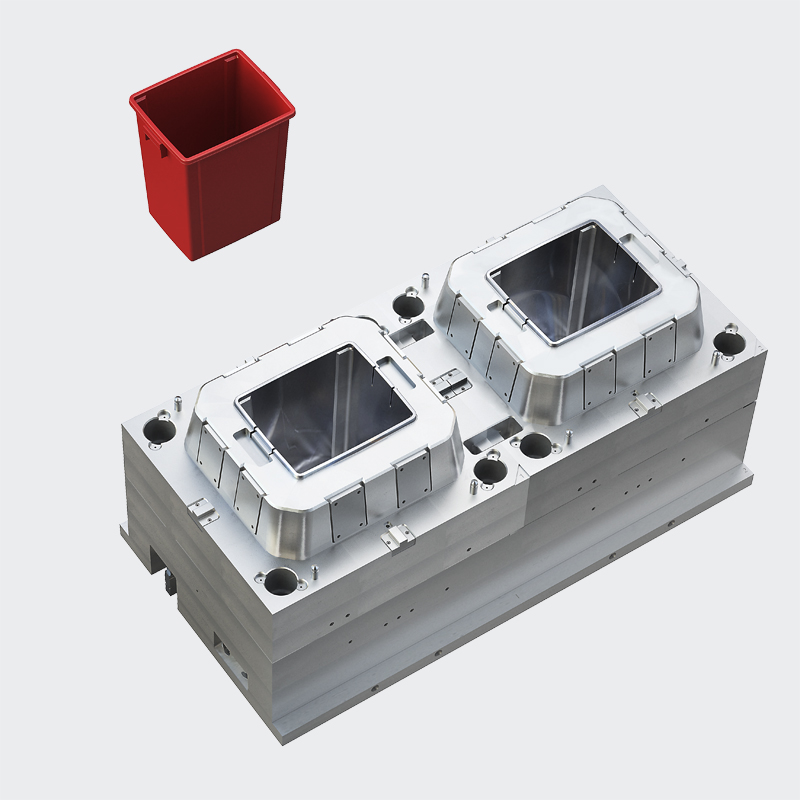

An auto parts mould is a specialized industrial tool that produces molded plastic automotive components. This type of molding can be used to produce a variety of different components, including bumpers, car dashboards, and seat pads.

Using this type of injection molding technique to manufacture automotive parts allows manufacturers to achieve high quality, durable, and affordable products. Injection molded components are also able to resist a range of environmental elements, such as weather conditions and chemical exposure.

The process of injection molding is a highly scalable manufacturing method, which means that as more parts are produced with the technique, production costs decrease. This is due to the low cost of thermoplastics and the short cycle time.

Injection molded components are typically smooth and free of defects, making them ideal for use in a variety of applications. Manufacturers have a wide selection of surface finishes, which they apply directly to the mold rather than on the part itself. However, the final finish will vary depending on the polymer material being used and the design of the component.

Advantages of Using Injection Molding for Automobile Parts

Compared with other types of plastic molding processes, such as die casting, injection molding is the most scalable and efficient method for producing automotive components. The process is compatible with a variety of plastic materials, which can help manufacturers avoid delays in sourcing complicated materials.

The most common auto parts molded with plastic are vehicle door edges, bumpers, hoods and front covers, interior trim, and sunroof components. These components often have complex geometries and require a high level of precision to manufacture.