Creating automobile parts using plastics can save energ […]

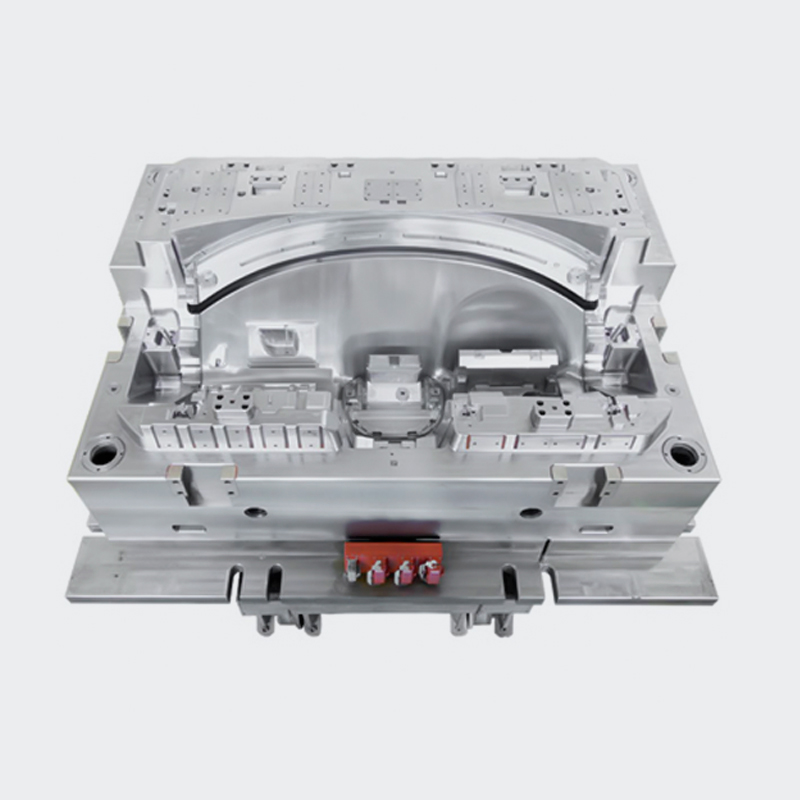

Creating automobile parts using plastics can save energy and reduce the weight of the car. Plastics also provide a great deal of flexibility for designing a car.Injection molding is a highly repeatable process. It is a popular manufacturing process that is used by automotive manufacturers. It is compatible with many different types of plastics, including polycarbonate, nylon, acrylic and polypropylene.The process involves heating up the raw material until it is soft, then putting it into a mold. When the plastic is poured into the mold, it is shaped to the desired size and shape. Depending on the materials used, plastic parts are durable and have similar properties to metal parts.

Injection molding is often used by automotive manufacturers for mass production, as well as prototyping. Injection molding is a cost effective process, but requires an initial investment in molds and tools.The process is also highly scalable, making it ideal for mass production. As more parts are made, the production cost will decrease. It is also very reliable. If the mold has a good design and finishing, the process is highly repeatable.

Auto parts molds are often made of thermoset plastics. These materials are more durable than metal parts and are usually lighter. This means that they can be used to make auto parts that have complex geometry.The process requires a great deal of attention to detail. It is important to work with an experienced auto parts mould manufacturer.