The wall thickness of plastic injection molded parts ha […]

The wall thickness of plastic injection molded parts has a great impact on the overall quality, processing speed and operation cost of products. Therefore, we must attach great importance to the problem of wall thickness in plastic mold manufacturing.

Advantages of uniform wall thickness:

The resistance of cooling stage is reduced

Rapid cooling reduces injection time.

Reduce the overall weight of products to facilitate handling, management and freight.

The overall cost is reduced, the use of raw materials is reduced and the turnover time is accelerated

Influence of improper wall thickness

In the cooling stage of the manufacturing process, it is necessary to have uniform wall thickness. If some areas of the product are thinner than others, the area may be prone to twisting, warping, cracking or collapsing. Appropriate wall thickness reduces the residual stress and shrinkage of the finished product.

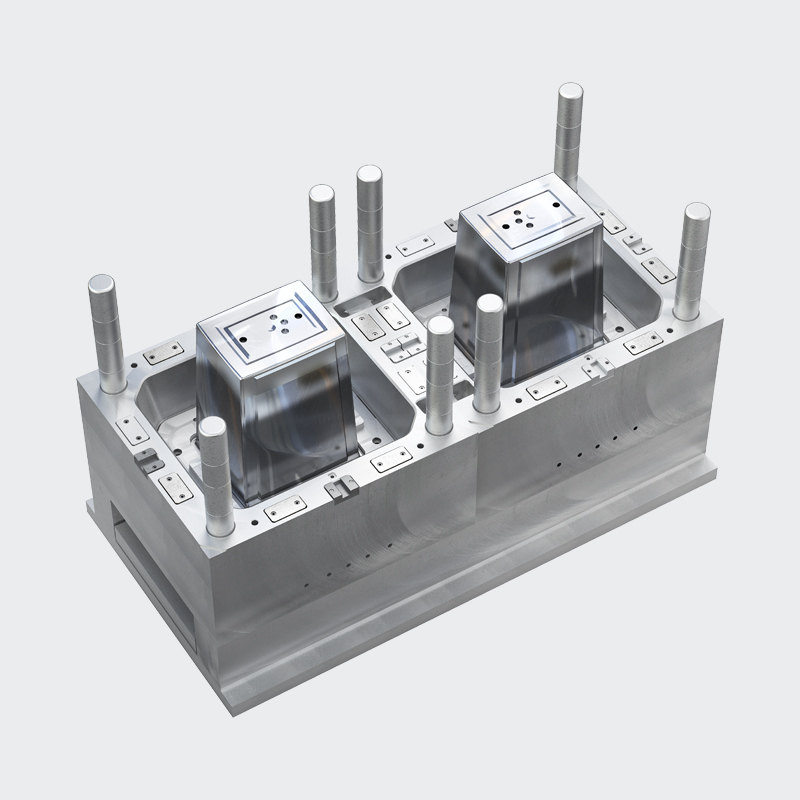

Taizhou Huangyan Mengsheng Plastic Mould Co., Ltd.