An air cooler mold is a tool used to shape and form pla […]

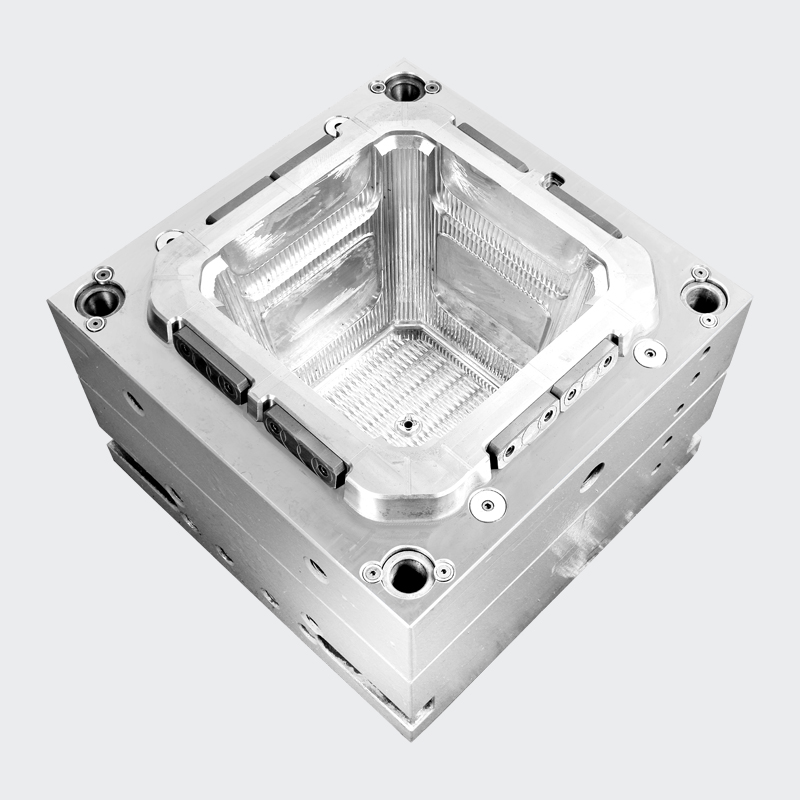

An air cooler mold is a tool used to shape and form plastic or metal into the desired shape of an air cooler. Air coolers are devices that use air to cool and circulate air in a room or enclosure. They often consist of a fan, a cooling element such as ice or water, and a system for distributing the cooled air. The mold is used to shape the various parts of the air cooler, such as the housing, the fins, and the air intake and output vents. Molds can be made of metal or plastic, and are usually made using a process called injection molding, in which the material is heated and injected into the mold under high pressure.

Air cooler moulds are typically designed to produce parts for air coolers, which are devices that use air to cool down a space or an object. Some characteristics of air cooler moulds may include:

Size: The size of the mould will depend on the size of the air cooler being produced. Moulds for smaller air coolers may be smaller in size, while moulds for larger air coolers may be larger.

Shape: Air cooler moulds can have a variety of different shapes, depending on the design of the air cooler being produced. Some common shapes include rectangular, circular, or hexagonal.

Material: Air cooler moulds are typically made from a durable material such as metal or plastic, as they will be subjected to high temperatures and pressure during the manufacturing process.

Precision: Air cooler moulds need to be highly precise in order to produce parts with the correct dimensions and tolerances.

Ejector systems: Air cooler moulds may include ejector systems to help release the finished parts from the mould.

Cooling systems: Air cooler moulds may also include cooling systems to help cool down the mould and the finished parts during the manufacturing process.