Although the structure of the mold may vary greatly due […]

Although the structure of the mold may vary greatly due to different types and properties of plastics, shapes and structures of plastic products, and types of injection machines, the basic structure is the same. The mold is mainly composed of gating system, temperature regulating system, molding parts and structural parts. Among them, the gating system and molding parts are the parts that directly contact with the plastic and change with the plastic and products. They are the most complex parts in the plastic mold with the greatest change, and require the highest processing finish and precision.

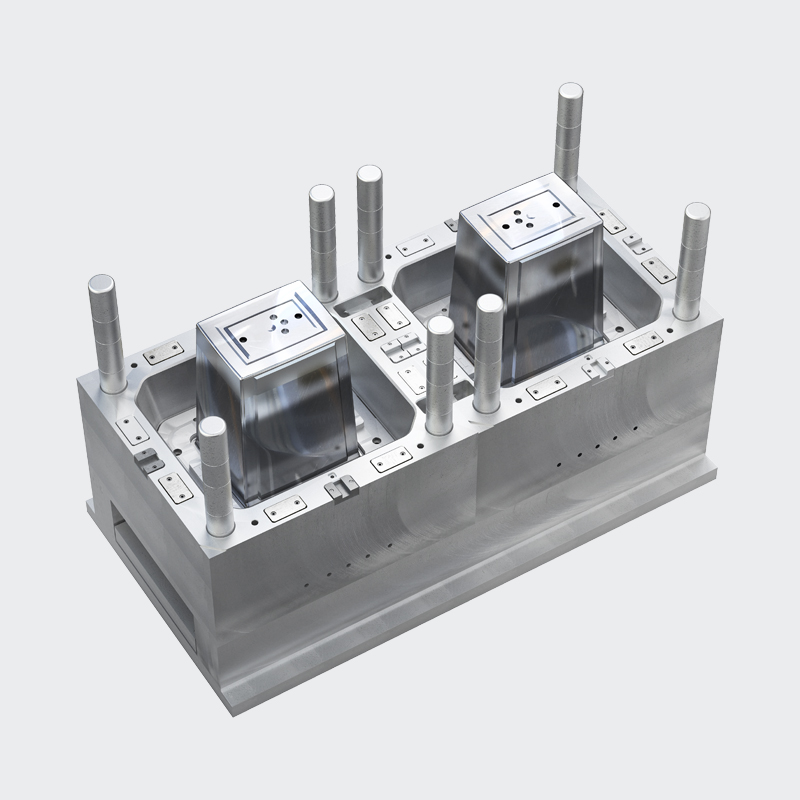

The injection mold consists of a moving mold and a fixed mold. The moving mold is installed on the moving template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form a gating system and a mold cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic products. In order to reduce the heavy workload of mold design and manufacturing, most injection molds use standard mold bases.

The gating system refers to the runner part before the plastic enters the mold cavity from the nozzle, including the main runner, cold material cavity, splitter channel and gate.

Gating system, also known as runner system, is a group of feeding channels that lead the plastic melt from the injector nozzle to the mold cavity. It is usually composed of main runner, branch runner, gate and cold cavity. It is directly related to the molding quality and production efficiency of plastic products.